Contour Cutters & Profile Cutters

Hot Wire Horizontal Grid Contour Cutter – GP-5100

- Standard Block Capacities – 1,2,3 block wide models – 8′ to 24′ lengths

- GP-PC11 Computer Controller – utilizes industry standard “M / G code” Standard

- Large Color LCD Screen – illustrates part being cut

- Foam Cutting Software Installed – interfaces with most cad/cam software

- “Cutting Edge” Power Supply – GFI protected

- Top Down Cutting Direction Reduces Part Distortion Caused by “Drop”

- Ethernet 10base-T connectivity

- Wire Break Detection (optional)

- Digital or Analog Voltage, and feed rate Displays (optional)

- Custom Design to Your Specifications – Our design staff is ready to meet your Specific requirements

Features Listed May Not Be Standard On All Models

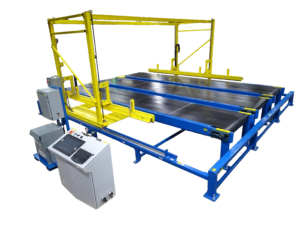

Hot Wire Vertical Grid Contour Cutter – GP-5000

- Standard Block Capacities – 1,2,3 block wide models – 8′ to 24′ lengths

- Rigid Moving Gantry – standard contour grid, optional vertical and trim wire grids

- GP-PC11 Computer Controller – utilizes industry standard “G / M code” format

- Large Color LCD Screen – illustrates part being cut

- Foam Cutting Software Installed – interfaces with most cad/cam software

- “Cutting Edge” Power Supply – GFI protected

- Ethernet 10base-T connectivity

- Automated Block Handling (optional)

- Computer Controlled Turntables (optional)

- Spindle and Column Attachments (optional)

- Digital or Analog Voltage Displays (optional)

- Digital or Analog Feed-rate Displays (optional)

- Wire Cooling Systems (optional)

- Intermediate Wire Support (optional)

- Wire Break Detection (optional)

- Custom Design to Your Specifications – Our design staff is ready to meet your specific requirements

GP-PRO 500

- Counter Balanced Cutting Head Glides Effortlessly Over Template

- Straight Line Cutting, and Circular Cutting Capability May be Utilized to Accurately Reproduce Parts

- Variable Temperature Power Supply

- Product Squaring Guides

- Linear Slide Assemblies for Up/Down, and Side/Side Travel – produces smooth cuts

- 4′ x 4′ x 8′ Standard Block Capacity – other sizes available

Features Listed May Not Be Standard On All Models

Features Listed May Not Be Standard On All Models

GP-Multi-Axis Milling Machine

This Computer Controlled System Is Perfect For Foam Processing And Model Making With Contour And Profile Capabilities. The Machine Features A High Speed Cutting Spindle For Vibration Free Material Removal.

- Axis Travel X = 40″, Y= 30″, Z= 40″ – other travel lengths available

- User Friendly Computer Interface

- Choice of Table Configurations – Aggressive surface with hold downs, or Vacuum table

Features Listed May Not Be Standard On All Models

GP-Lathe

- Creates Tapered, Fluted, and Standard Columns

- Rigid Steel Frame

- Precision Linear Slide Assemblies

- Large Spindle / Column Capacity

- Three Axis Control to Precisely Control Spindle Speed, Feed Rates, All Controlled Via GP-PCII Controller, or Standard Drive System Model Available

- Adjustable Tail Stock

- Head and Tail Stock Incorporate Special Tines to Hold Material Securely